Ningbo jiangbei Hongsheng High-voltage Electric Hydraulic Machinery Co.,LTD.(hereinafter referred to as Ningbo Hongsheng Company),founded in 2000,is located in Ningbo, a beautiful city with convenient transportation. It has passed ISO9001:2015 international quality system. This company covers an area of 16000 square meters, with a building area of 10000 square meters.

Hongsheng Company has always been adhering to the principle of ”integrity , quality, efficiency, profession”, and it acts of acts consistently with its motivation-create products with its unique characteristics.This company owns advanced equipment, a team of design, production and management, which is organized by experienced senior talents,and strong product design and development ability and mechanical processing capacity.

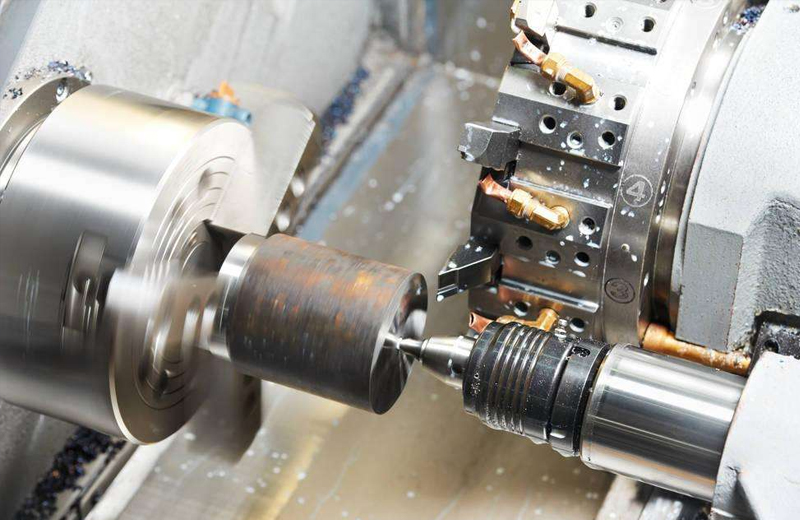

Comfortable and safe working environment, sophisticated advanced equipment

pursue subsistence on quality, and seek development with credibility

Adhere to the production of distinctive products as a target

CNC machining is a process that is widely used in the machining industry, which refers to the process of machining parts on CNC machine tools. CNC machining, CNC machine tools will be used, CNC system, CNC machine tool is a kind of computer to control the machine tool, and CNC system instructions by the programmer based on the workpiece material, processing requirements, machine tool features and systems A set of instructions prepared by the prescribed instruction format.

Mechanical processing machinery parts and auxiliary equipment is an important part of CNC machine tools. Among them, the mechanical parts mainly include: machine tool spindle parts, ball screw nut, rail and so on. The auxiliary devices are mainly include: CNC indexing head, automatic tool change device, hydraulic pressure system and cooling lubrication device. Therefore, their daily maintenance and maintenance of CNC machine tools is one of the maintenance and care work.

With the continuous development of precision machining industry in mechanical processing plants, precision machining requirements are constantly improving. Precision machining technology is a manufacturing technology applied in recent years, so it is more suitable for thin-walled parts.

For mechanical processing plants as a whole affected by the multiple factors both at home and abroad, such as the global financial crisis and the global economic slowdown, the internal and external demand of the entire machinery industry has accelerated its slowdown. The accumulated sales volume of the machinery industry grew by 25% Value growth rate of 17%.